Ppk is a process performance index which tells how well a system is meeting the specifications. It is measure the distance from the process mean to the closest specification limit (USL or LSL).

Ppk is expressed as the following:

Ppk = Minimum (Ppu, Ppl)

Ppu = (USL - X̄)/3s

Ppl = (X̄ - LSL)/3s

Where, Ppk is the minimum of Ppu and Ppl. ‘Ppu’ is the capability based on the upper specification limit (USL), ‘Ppl’ is the capability based on the lower specification limit (LSL), and ‘s’ is the calculated standard deviation from all the data.

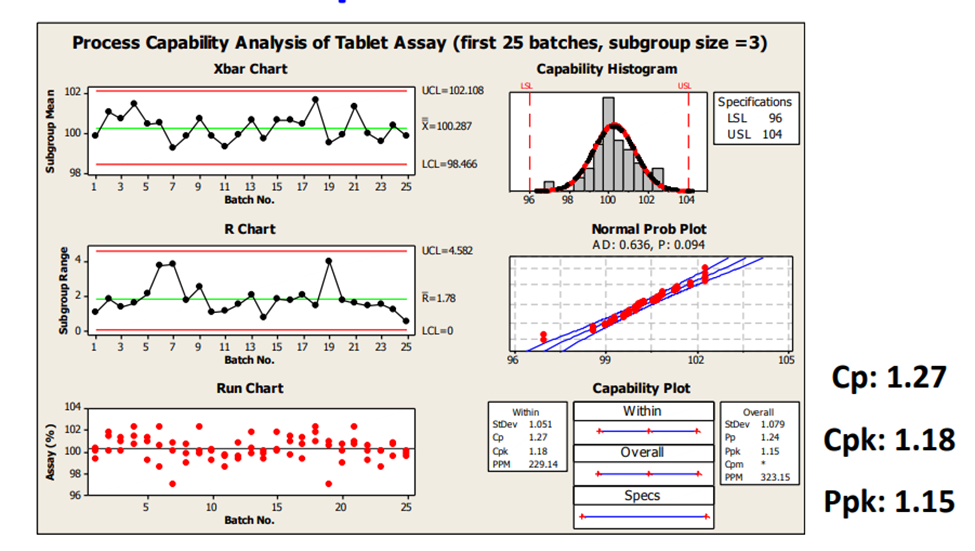

Difference between Cpk & Ppk

Cpk only accounts for the variation within the subgroups, where Ppk accounts for the overall variation of all measurements taken.

Example of Xbar-R Chart

Relationship between Cpk & Ppk

If the process is stable, Ppk = Cpk, i.e. the actual performance will match the predicted potential performance. However, if the process is unstable (i.e. if it shifts or drifts over time); you will find Ppk << Cpk.

Post a Comment